Automated Coverslipper Medical device

Automated Coverslipper Medical device Specification

- Material

- ABS Resin and Stainless Steel

- Condition

- New

- Technology

- Automated Coverslipping with microprocessor control

- Portable

- Bench-top model, semi-portable

- Disposable

- Compatible with standard disposable coverslips

- Wall Mounted

- No

- Light Source

- LED Indication for Operation Status

- Air Pressure

- Automatic regulated dispenser mechanism

- Display Type

- LCD status display

- Resolution

- Operational status, not image resolution

- Sensor

- Integrated position and safety sensor

- Internal Memory

- Stores up to 30 coverslip parameters

- Software Detail

- Embedded controller menu for cycle management

- Measurement

- Automated coverslip placement accuracy within 0.1mm

- Data Transmission Mode

- USB port for firmware upgrades

- Synchronize With

- Laboratory workflow management systems

- Real-Time Operation

- Yes, with programmable control

- Operating Type

- Fully automated cycle initiation

- Noise Level

- < 60 dB during coverslipping process

- Power Source

- Mains

- Power Consumption

- 100W max during operation

- Voltage

- 220-240V AC, 50/60Hz

- Battery

- Not applicable (mains powered)

- Light

- LED operational indicator

- Size

- 430 mm x 330 mm x 250 mm

- Weight

- Approx. 16 kg

- Color

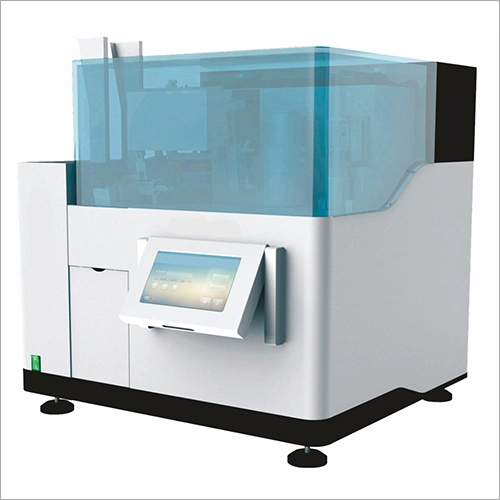

- White and blue

- Usage

- Automated coverslip placement for microscopy slides

- Attributes

- Easy slide loading, error alert system

About Automated Coverslipper Medical device

Automated Coverslipper Medical Device offered by us is greatly admired for easing laboratory operations while increasing speed. It is intended to be used for automatically applying coverslips to microscopic slides in bubble-free manner. This device is completely suitable to be employed in histopathology & hematology laboratories. It is provided with user-friendly touchscreen control panel for making it easy to navigate through different parameters. Automated Coverslipper Medical Device can process large stack of slides in single cycle which enhances its efficiency.

Features:

- Better human-machine interface

- Does not break any of the slides

- Smooth & fast operation

Advanced Automated Slide Coverslipping

Improve laboratory efficiency with this fully automated coverslipper, enabling rapid and accurate coverslip placement. With its ability to handle up to 300 slides per hour and integrated safety features such as door interlock and jam detection, it minimizes manual intervention and potential errors. The intuitive touchscreen interface supports multiple languages, making operation straightforward for users in diverse settings.

Intelligent Design & Reliable Performance

This device boasts adjustable environmental controls, programmable cleaning, and precise coverslip placement within 0.1mm. The regulated adhesive environment ensures optimal results with various mounting media, while real-time operational status and an LED indicator keep users informed. Internal memory stores up to 30 coverslip parameters, ensuring consistency across different protocols and workflows.

FAQs of Automated Coverslipper Medical device:

Q: How does the automated coverslipper ensure precise coverslip placement on slides?

A: The coverslipper uses a microprocessor-controlled mechanism with integrated position and safety sensors, delivering precise coverslip placement within 0.1mm. Automatic regulation of the dispenser and programmable operation further enhance accuracy.Q: What types and sizes of slides are compatible with this device?

A: This coverslipper accommodates standard 25 x 75 mm and 1 x 3 inch microscope slides, ensuring compatibility with the most commonly used slide formats in laboratories.Q: When should the devices cleaning and maintenance cycles be performed?

A: The coverslipper features programmable cleaning and maintenance prompts. It alerts users when cleaning or calibration is required, which helps maintain optimal performance and prolongs device life.Q: Where can the automated coverslipper be installed in the laboratory?

A: Designed as a bench-top, semi-portable unit, the device can be placed on any appropriate laboratory workbench. It does not support wall mounting and requires a stable surface with access to a standard 220240V AC power supply.Q: What is the process for loading coverslips and slides into the machine?

A: Slides and coverslips are loaded into dedicated trays and dispensers. The automatic coverslip dispenser holds up to 150 coverslips, and the user-friendly menu guides operators through loading procedures, ensuring smooth workflow integration.Q: How does the device maintain optimal adhesive performance?

A: A regulated humidity control system ensures that environmental conditions are maintained for the best adhesive results, preventing drying or curing issues during coverslipping.Q: What are the main benefits of using this automated coverslipper in the laboratory?

A: Key benefits include rapid throughput, minimized manual intervention, enhanced safety, precise coverslip placement, multi-language support, and integration with laboratory workflow systems, resulting in increased efficiency and consistent slide preparation quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

BIONEON DIAGNOSTICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry